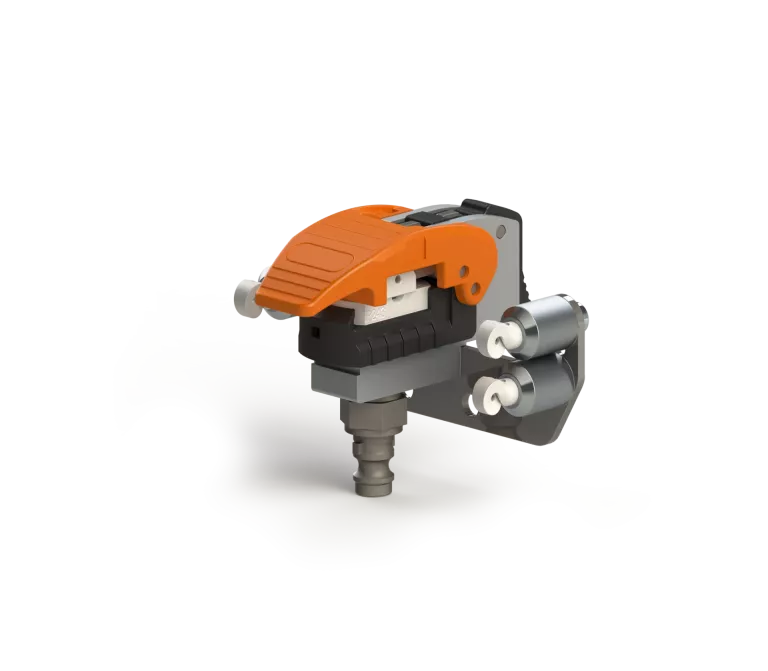

The SlideJet-HFP15-2 is used during the cost-effective manufacture and processing of filament yarns during the air covering process. The jet is a modular system with a universal quick-lock housing and numerous easily replaceable jet inserts.

HEBERLEIN. SLIDEJET-HFP15-2.

Features and Benefits.

Assortment.

Series APh

Designed to ensure maximum knot stability for downstream processes, such as weaving. A comprehensive series of tests have shown that up to 100% stability can be achieved at a load of 1 cN/dtex. This allows higher machine speeds and results in increased productivity. Alternatively, the sizing application can be reduced, which has a positive impact on costs and the environment.

Series Px1x

Tried-and-tested series P211-2 to P412-2 with vortex chamber for particularly high interlacing stability. For all combinations of elastane with textured and staple fibre yarns up to 700 m/min.

Series Px4x

Series P141-2 to P247-2 with patented air twist chamber for very regular interlacing with a maximum number of interlacing knits up to speeds of 1,000 m/min.

Technical data.

Application area

| Type | Typical range [dtex] | (Max. limits of application) |

|---|---|---|

| Medium interlacing density – high to very high stability | ||

| APh212 | 78 … 167 | (50 … 240) |

| APh213 | 167 … 330 | (110 … 390) |

| APh215 | 240 … 450 | (167 … 660) |

| Medium interlacing density – medium to high stability | ||

| P211-2 | 50 … 95 | (20 … 110) |

| P212-2 | 78 … 167 | (50 … 240) |

| P213-2 | 167 … 330 | (110 … 390) |

| P215-2 | 240 … 450 | (167 … 660) |

| P312-2 | 330 … 660 | (240 … 720) |

| P412-2 | 660 … 990 | (560 … 1200) |

| High interlacing density – medium stability | ||

| P141-2 | … 50 | (… 67) |

| P142-2 | … 67 | (… 95) |

| P143-2 | 50 … 95 | (… 110) |

| P243-2 | 78 … 167 | (67 … 200) |

| P244-2 | 167 … 330 | (95 … 390) |

| P246-2 | 240 … 450 | (200 … 560) |

| P247-2 | 450 … 720 | (390 … 800) |

Air consumption per thread

| Type | Air channel diameter | Formula |

|---|---|---|

| P141-2 | 0.9 mm | qvn = 0.376 x (pe + 1) |

| P142-2 | 1.1 mm | qvn = 0.562 x (pe + 1) |

| P143-2 | 1.24 mm | qvn = 0.712 x (pe + 1) |

| P243-2 | 1.4 mm | qvn = 0.911 x (pe + 1) |

| P244-2 | 1.57 mm | qvn = 1.142 x (pe + 1) |

| P246-2 | 1.77 mm | qvn = 1.451 x (pe + 1) |

| P247-2 | 2.0 mm | qvn = 1,785 x (pe + 1) |

| P211-2 | 1.30 mm | qvn = 0.786 x (pe + 1) |

| P212-2, APh212 | 1.4 mm | qvn = 0.911 x (pe + 1) |

| P213-2, APh213 | 1.6 mm | qvn = 1.189 x (pe + 1) |

| P215-2, APh215 | 1.8 mm | qvn = 1.506 x (pe + 1) |

| P312-2 | 2.05 mm | qvn = 1.859 x (pe + 1) |

| P412-2 | 2.5 mm | qvn = 2,772 x (pe + 1) |

Compressed air requirements

| Overpressure | 0.5 … 6.0 bar |

For the compressed air quality requirements, see Compressed air purity.

Request operating instructions.

Would you like to receive an operating manual for your product? Request now.